Scope of activity

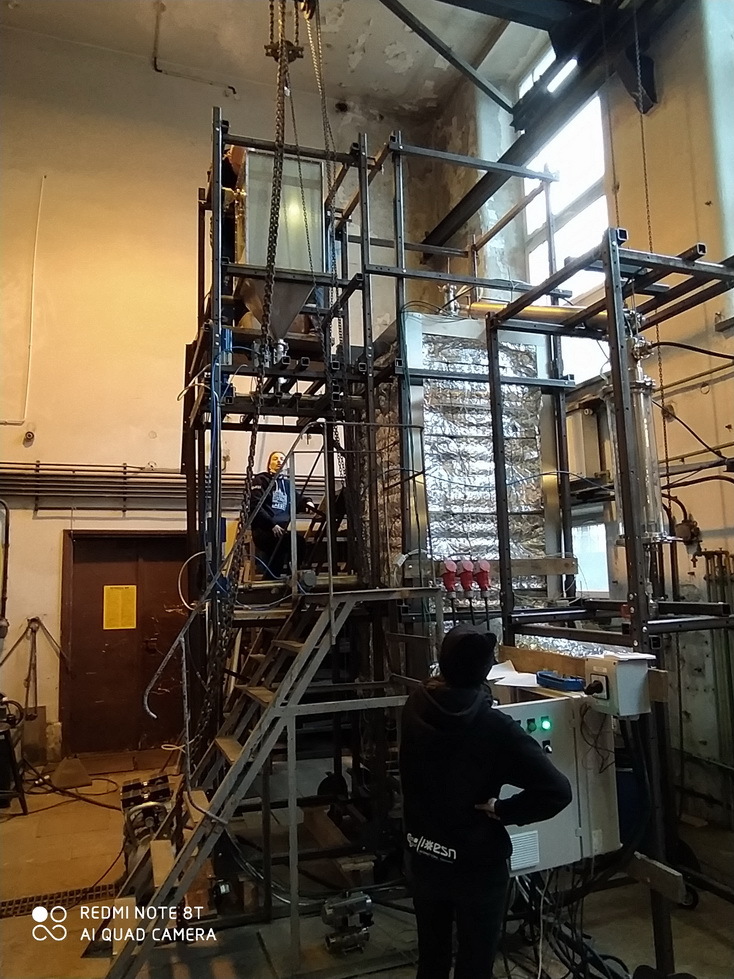

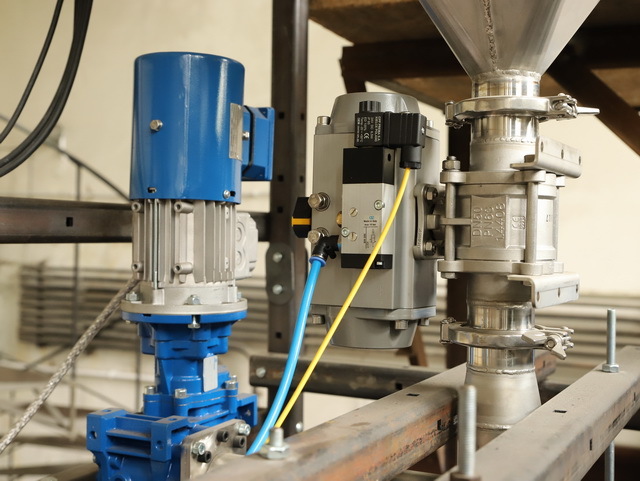

We build custom-made devices which are not available from manufacturers of standard equipment. We manufacture small devices and accessories, such as calorimetric bombs or mixers. We build components of research equipment, entire devices, as well as complete workstations. We also scale-up plants, from a laboratory large-scale to a pilot scale.

We understand the needs of scientists and the point of view of entrepreneurs. We know the issues of industrial implementations and the specifics of purchase in research projects. We use a variety of materials: stainless steel, copper alloys, aluminum alloys, plastic, ceramics, glass and other. We have a network of carefully selected subcontractors to whom we commission such works as machining, welding, water and laser cutting, surface finishing, and glass works. We deliver sophisticated solutions in automation, pneumatics and electronic control.

For enquiries regarding the construction of prototypes, please contact: prototyp@explosolution.com.