Since 2015, we have been active in the field of building prototype research equipment, which enables the implementation of technological processes on a laboratory to pilot scale. We create prototype apparatus designed to work at high temperature and vacuum and/or high pressure, suitable for aggressive media and equipped with ports for connecting various sensors.

We take care of socially important matters. Out of concern for the environment and human health, we develop technologies which are aimed at reducing the amount of generated waste and managing it on site (at the manufacturing plant). This not only reduces the emission of hazardous substances to the environment, but also eliminates transport, which has a direct impact on the safety of the population.

We are looking for innovative solutions in the field of chemistry and we use them in industrial research. They result in new technologies which can be implemented in Polish enterprises. We consult them with our partners already during the research work, so that the solutions best meet their needs.

Contact:

Explo Solution sp. z o.o. (Explo Solution Ltd.)

ul. Czerwonego Krzyża 2/5,

00-377 Warszawa

We provide the design and manufacturing of experimental research equipment for the needs of research units and industrial plants. We specialize in prototype solutions adapted to high pressures and temperatures. We participate in all stages of launching of the installation and testing research. We provide service and maintenance of the equipment.

We build custom-made devices which are not available from manufacturers of standard equipment. We manufacture small devices and accessories, such as calorimetric bombs or mixers. We build components of research equipment, entire devices, as well as complete workstations. We also scale-up plants, from a laboratory large-scale to a pilot scale.

We understand the needs of scientists and the point of view of entrepreneurs. We know the issues of industrial implementations and the specifics of purchase in research projects. We use a variety of materials: stainless steel, copper alloys, aluminum alloys, plastic, ceramics, glass and other. We have a network of carefully selected subcontractors to whom we commission such works as machining, welding, water and laser cutting, surface finishing, and glass works. We deliver sophisticated solutions in automation, pneumatics and electronic control.

For enquiries regarding the construction of prototypes, please contact: prototyp@explosolution.com.

Calorimetric bombs of various construction

Agitators of nonstandard construction (centrifugal, turbine and others)

Dies for casting propellants

Dies for pressing high-energy materials

Thermal and/or vacuum-pressure chambers, e.g.:

Bioreactors

Impact mill for grinding various materials

Workstation for the analysis of gunpowder exhaust gases and testing tank sensors

Laboratory and field workstations for testing the effectiveness of smoke screens

Planetary mixer for mixing explosives (Ex)

Pilot mixer equipped with a pneumatic liquid feeding system and a device for biomass ozonation in the air stream

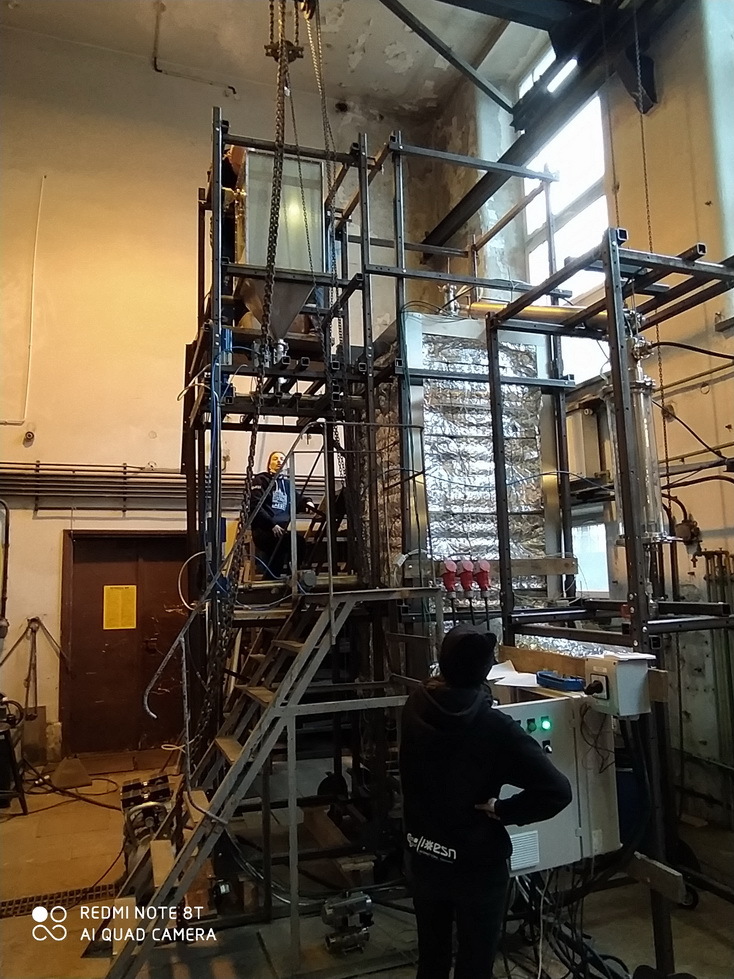

Continuous work vertical furnace with the capacity of 25kg/h of the processed charge - a pilot plant

We produce prototypes in the "fabless" model.

We define the problem to be solved together with the client, present possible solutions and agree on the optimal one. We design the device, select systems and materials, along with the subcontractors based exactly on the client's requirements. We coordinate and supervise production and control quality at every stage. We are responsible for the delivery, assembly and start-up of devices, as well as employee training.

Subsequently, together with the user, we find ways to improve previously built prototypes.

Calorimetric bomb, type I

Calorimetric bomb, type II

Bioreactor

Impact mill

Two shaft mixer for wet fodder with pneumatic sprinkler system

Biomass hygieniser in pneumatic transport (ozonation)

Continuous work vertical furnace

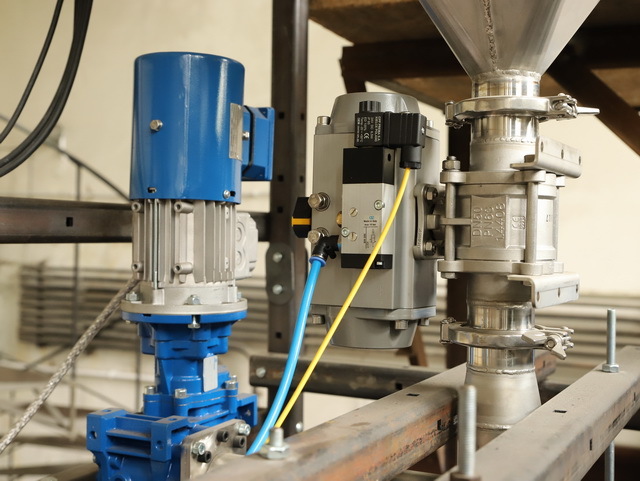

Drive of the furnace feeding system (electric motor and pneumatic valve)

Stainless steel condenser system

Aggregate from fly ash and organic waste

Aggregate grain in magnification

In our research for the industry, we engage primarily in questions connected to the environmental protection:

The use of combustion products in the manufacture of building materials

Coal combustion products (CCPs) or fly ash are widely used as an additive to cement. However ashes of different origin, including biomass combustion products and bottom ash or ash-slag mixtures remain unused so far. We offer a technology to use all these materials as a raw material for the manufacture of lightweight aggregate in a sintering process. An important element of our technology is an autothermic way of processing, which is provided by the feedstock of sufficiently large calorific value, i.e. the external energy source is not necessary except for the moment of start-up.

Technology of oxidation in supercritical water for the disposal of hazardous waste

Our solution is based on the conversion of organic waste to simple inorganic products (mainly CO₂, H₂O, and N₂) in supercritical aqueous solutions. The method utilizes specific physicochemical properties of water above its critical point (tc =374°C; pc= 22.1 MPa) and, in particular, its reduced viscosity and increased diffusion coefficient. Thanks to the supercritical water conditions the conversion of organic compounds containing nitrogen into environment-friendly N₂ is thermodynamically favoured over the conversion to toxic nitrogen oxides (NOₓ).

We aim to ensure the exothermic effect of the reaction which should sustain the oxidation process. In some cases the configuration is even able to generate a redundancy of heat, which may be used externally. Our solutions are, in our opinion, perfectly dedicated for the utilization of water-soluble organic waste that are difficult to separate from the waste water. They can be also successfully applied to the utilization of water-immiscible organic waste, in the form of an emulsion or suspension. Our solution is ideal for the improvement of water management processes. It guarantees recovery of water purified of organic waste, at the same time eliminating and not just concentrating waste. In addition, the conversion of organic waste in supercritical water solutions is much greener than traditional combustion methods which are a heavy burden to the environment.

Processing of industrial wastewater containing heavy metals

Processing of hazardous waste is a very complex issue and one of its most important problems is the content of heavy metals. Their presence forcibly suppresses the growth of microorganisms used in the bioconversion of waste. We conduct research on the use of sorbents based on natural lignocellulosic materials (wood, bark, straw) for the selective binding of metal ions. The most important issue, from the point of view of the effectiveness of the process, is a microporous structure of these sorbents. Our research focuses on changing this structure by the means of physical, chemical, thermal and mechanical methods. We use a modern method of reverse exclusion chromatography, which allows for analysis of wet porosity materials in conditions corresponding to the technological processes. We mark the effectiveness of sorbents by analysing the chemical composition of the sorbents and waste, as well as the toxicity to aquatic organisms (Lemna minor, Daphia sp., Artemia salinas)

Energetic utilization of by-products of chemical processes

Many technologies of chemical, pharmaceutical, wood or agro-food industries produce by-products that are difficult to process, and as a result they become waste, often dangerous and burdensome to the environment. We offer a solution which utilises them as a source of extra energy that could be used by an enterprise. A specific technology is adapted to the particular substances generated at the client's enterprise. The key issue is to provide such oxidation conditions which eliminate the creation of harmful gases, especially nitrogen and sulphur oxides.

Biofuel technologies, including biofuels obtained of wood production waste and postconsumer waste

In Poland an intensive research on the technology of second generation bioethanol obtained from lignocellulosic biomass has been carried out. Wood, straw and agricultural waste, among others, have been tested as the raw material. On the other hand, in Poland there is a very well-developed wood industry, which generally does not generate pure wood waste. However an important problem is processing industry of wood materials containing different kinds of glues and resins, typically urea-formaldehyde and phenol-formaldehyde. Post-production waste (edgings, dust), as well as postconsumer waste (old cabinets, shelves, panels, etc.) constitute a material that is not suitable for recycling and at the same time cannot be used directly as a fuel. Explo Solution is developing a technology of pre-treatment of such waste materials, allowing their use as raw materials used to produce bioethanol. We place the main emphasis on the following aspects in our studies: the decomposition of formaldehyde resins, protection against emission of formaldehyde and phenolic compounds into the environment, the microstructure of wood and its accessibility to the hydrolytic enzymes. Our technology will not only increase the raw material base for bioethanol technology but also creates a solution to the problem of processed wood waste.

We offer product analyses using the latest analytical techniques including spectroscopy and chromatography. The analyses are performed in our own laboratory or on the equipment rented from our research partners (universities and research institutes). The analyses include both product composition tests and performance parameters tests.

We cooperate with schools and universities. We provide lectures on the construction of machines and chemical apparatus at Warsaw University of Technology. We supervise engineering and master's theses, together with the scientists, in which research is carried out on the equipment, which we have constructed.